3D Printing Market Size to Reach USD 136.76 Billion by 2034 | CAGR- 21.60% (2026-2034)

The global 3D printing market is set to expand at a 21.60% CAGR through 2034, driven by customization demand, industrial digitization, and advanced materials.

3D Printing Market Size to Reach USD 136.76 Billion by 2034, Driven by Rapid Adoption of Additive Manufacturing”

PUNE, MAHARASHTRA, INDIA, January 29, 2026 /EINPresswire.com/ -- The global 3D printing market was valued at USD 23.41 billion in 2025 and is projected to grow from USD 28.55 billion in 2026 to USD 136.76 billion by 2034, registering a robust CAGR of 21.60% during the forecast period. The market’s strong momentum is fueled by rising adoption of additive manufacturing technologies across aerospace, automotive, healthcare, consumer goods, and industrial manufacturing sectors.— Fortune Business Insights

3D printing is increasingly being adopted to meet the growing demand for customized, lightweight, and complex components, while simultaneously reducing material waste and production lead times. Advancements in printing materials, software integration, and industrial-scale printers are further accelerating market growth. In addition, increasing investments in Industry 4.0 initiatives and digital manufacturing ecosystems continue to strengthen the long-term outlook of the market.

Get a Free Sample PDF- https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/3d-printing-market-101902

North America dominated the global 3D printing market with a 40.80% share in 2025, supported by strong technological infrastructure, high R&D investments, and early adoption of advanced manufacturing technologies. The region continues to benefit from increasing demand for additive manufacturing solutions across multiple end-use industries.

3D Printing Market Takeaways

The market is witnessing sustained growth due to rising industrial adoption, increasing demand for rapid prototyping, and expanding applications in healthcare and aerospace. Continuous innovation in materials and printer capabilities is strengthening market scalability.

3D Printing Market Trends

1. Rapid Adoption of Additive Manufacturing Across Industries

Across aerospace, automotive, healthcare, and industrial manufacturing, companies are increasingly using 3D printing not just for prototyping but for end-use part production, driven by demand for lighter, stronger, and more complex parts.

2. Shift from Prototyping to Production

Advancements in printer capabilities, materials, and repeatability have transformed 3D printing from a prototyping tool to a mainstream production technology, enabling scalable manufacturing for serial components.

3. Growing Demand for Customization

Consumers and industrial buyers alike are demanding tailored products — from patient-specific medical implants to bespoke industrial parts — which has accelerated use of 3D printing for mass customization.

4. Material Innovation (Metals, Polymers & Composites)

Expansion of printable materials, especially high-performance polymers, composite blends, and metal powders, is unlocking new applications in sectors where strength, heat resistance, and performance are critical.

3D Printing Market Segmentation Analysis

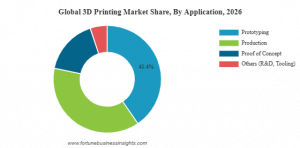

By component, the market is segmented into hardware, software, and services, with hardware accounting for a significant share due to rising deployment of industrial printers. Based on technology, fused deposition modeling (FDM), stereolithography (SLA), selective laser sintering (SLS), and direct metal laser sintering (DMLS) are widely adopted. By end-user, aerospace & defense, healthcare, automotive, and industrial manufacturing represent key demand-generating sectors.

By Component

Hardware holds a significant share, driven by rising adoption of industrial and desktop 3D printers across manufacturing, healthcare, and aerospace sectors. Continuous advancements in printer speed, precision, and build volume support demand.

Software demand is growing steadily due to the need for advanced design, simulation, slicing, and workflow management tools that enhance printing accuracy and production efficiency.

Services are witnessing strong growth as organizations increasingly outsource printer maintenance, training, design consulting, and on-demand printing to reduce capital expenditure.

By Technology

FDM (Fused Deposition Modeling) dominates in volume adoption due to low cost, ease of use, and wide material compatibility, particularly for prototyping and education.

SLS and SLA are widely used for high-precision prototyping and low-volume production, offering superior surface finish and mechanical properties.

DMLS/SLM and EBM are gaining traction in aerospace, automotive, and medical applications owing to their ability to produce complex metal components with high strength.

PolyJet and Multi Jet Fusion enable high-resolution, multi-material printing, supporting functional prototyping and end-use parts.

DLP, Binder Jetting, CLIP/CDLP, SDL, and LOM serve niche and specialized applications, with adoption increasing in dental, casting, and high-speed production environments.

Speak To Analyst- https://www.fortunebusinessinsights.com/enquiry/speak-to-analyst/3d-printing-market-101902

Regional Insights

North America holds the largest market share, driven by increasing demand for customized manufacturing solutions across industries. The U.S. market is projected to reach USD 6.98 billion by 2026 and is expected to grow significantly, reaching USD 33,782.4 million by 2032, supported by strong adoption of additive manufacturing tools and advanced production technologies.

Europe represents the second-largest market share, supported by high adoption among small and medium-sized enterprises seeking cost-effective and high-speed prototyping solutions. Growth is particularly strong in manufacturing and semiconductor industries. The UK market is projected to reach USD 1.21 billion by 2026, while Germany is expected to reach USD 1.4 billion by 2026.

Asia Pacific is anticipated to register the highest CAGR during the forecast period. Government-backed initiatives promoting sustainable manufacturing and strong funding support are driving regional adoption. China remains the key growth engine, while Japan, China, and India are projected to reach USD 1.15 billion, USD 1.62 billion, and USD 0.56 billion respectively by 2026.

Middle East & Africa is expected to grow at the second-highest CAGR, driven by technological advancements and rising investments in additive manufacturing. Expanding industrial applications and funding initiatives are accelerating regional growth.

South America is witnessing steady growth supported by the development of regulatory frameworks, increasing adoption of advanced manufacturing technologies, and expansion of local production facilities.

List of Top Companies

3D Systems

Stratasys

HP Inc.

EOS GmbH

SLM Solutions

Materialise

Proto Labs

Ultimaker

Key Industry Developments

In December 2023, Immensa, a UAE-based additive manufacturing company, secured USD 20 million in funding led by Global Ventures to accelerate its global expansion strategy.

Leading market players are increasingly investing in metal additive manufacturing, industrial-scale printers, and advanced material development to strengthen their competitive positioning.

Strategic collaborations between software providers and hardware manufacturers are enhancing process automation and production efficiency across industries.

Related Reports-

3D Printing Ceramics Market

3D Printing Filament Market

Ashwin Arora

Fortune Business Insights™ Pvt. Ltd.

+1 833-909-2966

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.